Engineered for Seeds. Built Around You.

Tailored project solutions for every stage of seed processing

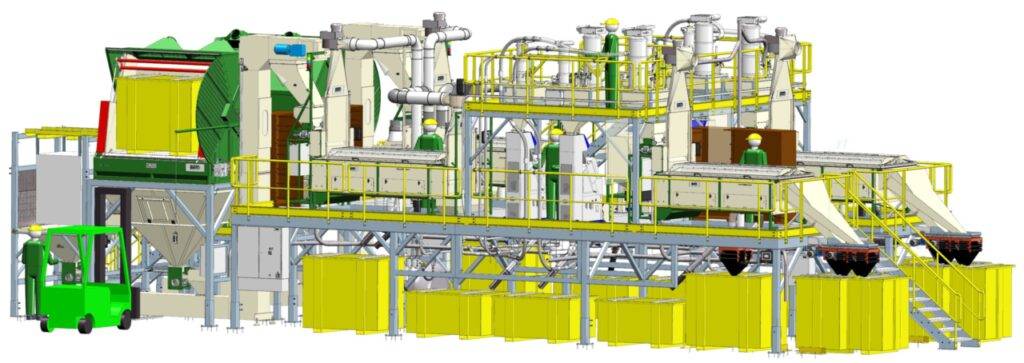

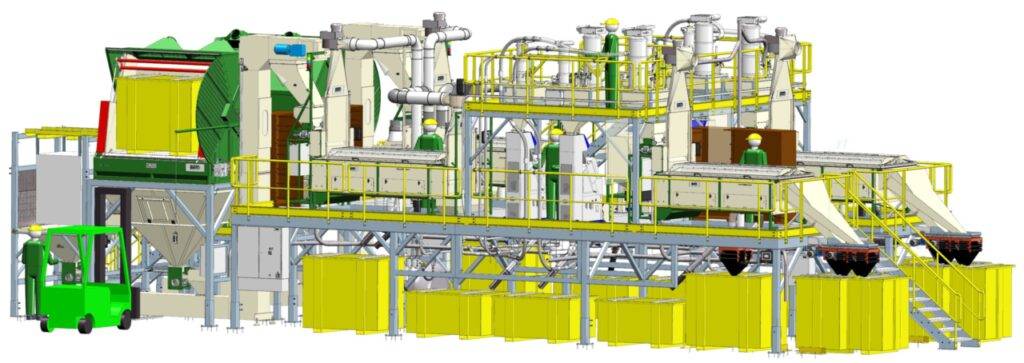

At Seed Processing Holland, we specialise in delivering turnkey seed processing solutions through structured, project-based collaboration. Whether you aim to upgrade existing installations or build new capacity, our approach ensures your operational and business goals are met. Efficiently, safely & on time.

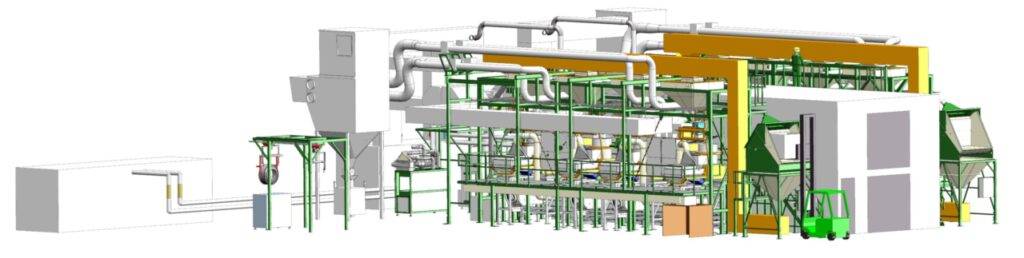

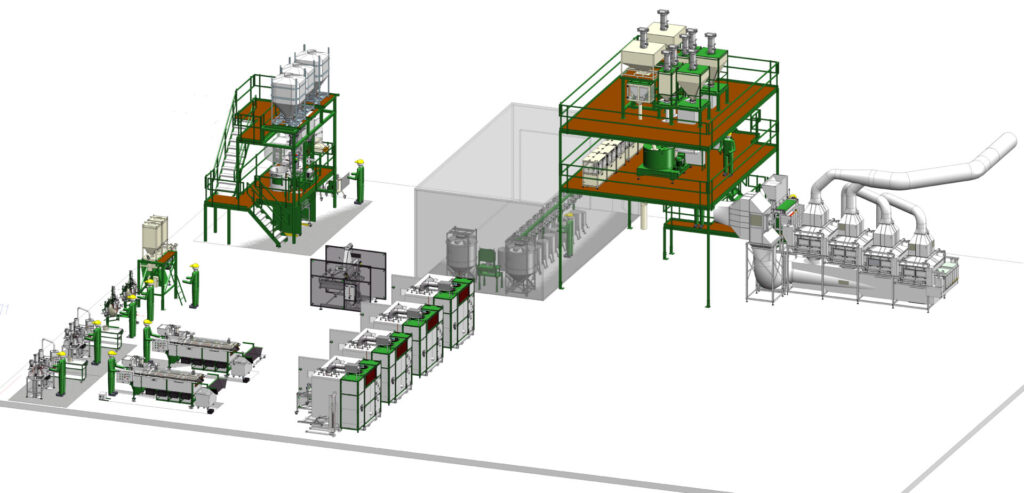

From the initial enquiry to final evaluation, our project engineers work closely with your team, translating your needs into custom-engineered systems. Each project starts with detailed engineering—including P&IDs, 3D layouts and quotations—followed by dedicated project management throughout execution. We manage planning, safety, utility integration, machine logistics and commissioning, ensuring alignment with your timeline and budget.

Ready to Start Your Project?

Whether you need a single installation or a complete facility upgrade—SPH is your trusted partner for project-based seed processing solutions.

Contact us today to discuss your goals and explore the possibilities.

Expert support for every Product Group:

Seed Extraction Solutions

We design extraction solutions based on crop type, lot size and process flow. For fruits like tomatoes, cucumbers and peppers, we offer equipment scaled for small batches up to large production volumes. Critical factors include water availability, drainage and fermentation needs.

Looking to optimise your extraction process? Our specialists will advise you on the ideal setup.

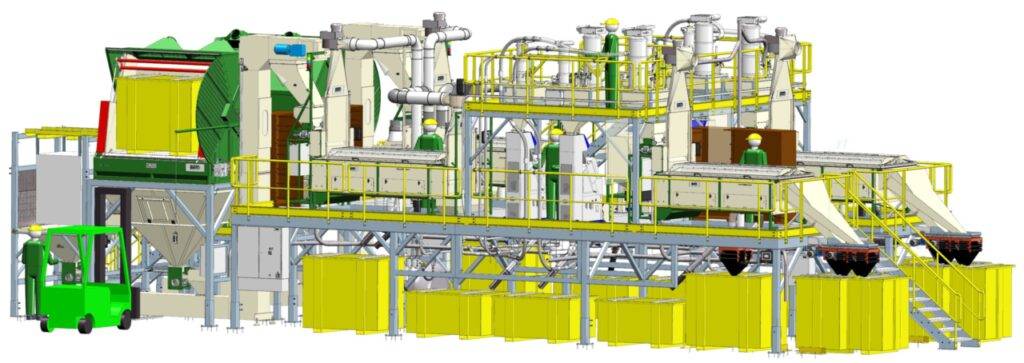

Seed Threshing Installations

Threshing dry crops—such as umbellifers, ears or pods—requires the right balance of technique and capacity. We help define the full setup: from drying and feeding logistics to waste handling and dust control, ensuring a seamless and clean workflow.

Need the right threshing line? Let us configure a solution tailored to your crop

Seed Disinfection Systems

Seed disinfection combats seed-borne diseases with precision. Together with your pathology team, we develop validated recipes and integrate safe, consistent machine-based disinfection—including waste management and process logging for traceability.

Secure your seed health. Ask us how to automate your disinfection line.

Seed Drying Installations

Drying is critical to maintaining seed viability. Based on your process data, we design energy-efficient drying lines with the right airflow, dehumidification capacity, and automation level to suit your seed types and volumes.

Ensure top-quality seed drying. Partner with SPH for a custom-engineered drying solution.

Seed Cleaning Systems

Seed cleaning demands precision. Our designs are based on input data such as seed type, purity levels, capacity and available space. We integrate Clean In Place™ systems to reduce downtime and improve hygiene between batches.

Achieve uncompromising seed quality with a cleaning solution engineered by SPH.

Seed Pelleting Installations

Pelleting improves seed handling and planting accuracy by creating uniform, round pellets. We design integrated pelleting lines that manage powders, liquids, dust control, and operator safety — all tailored to your capacity and process needs.

Ensure precise pelleting with a custom-engineered solution by SPH.

Seed Treating Systems

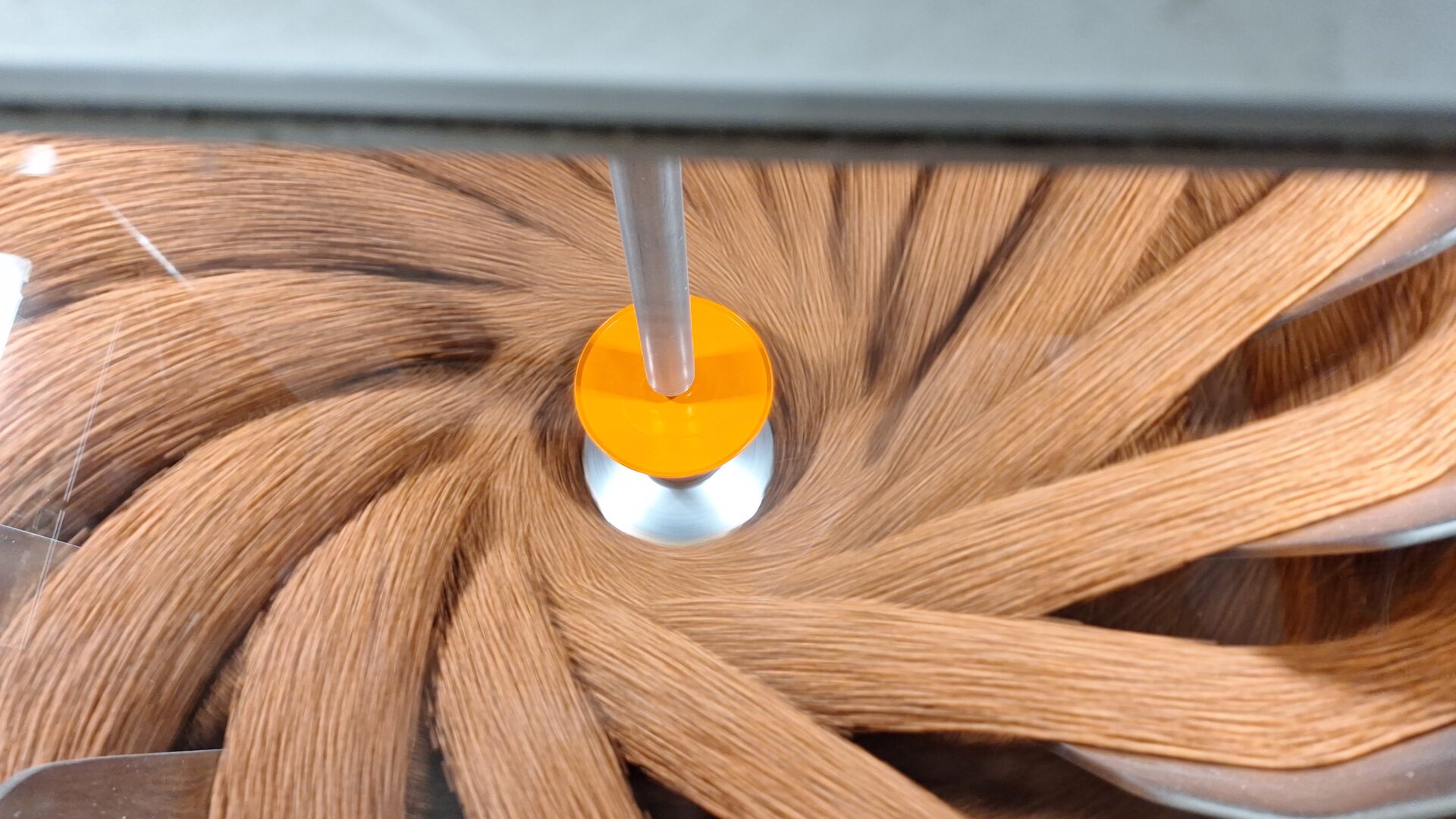

Seed treating protects seeds with precise application of chemical or biological agents. Our rotary coating and dosing systems ensure accurate coverage, with careful integration of liquid handling, discharge, drying, and safety measures — all tailored to your process.

Protect your seeds with a high-performance treating solution by SPH.

Seed Priming Installations

Seed priming boosts germination and breaks dormancy through controlled hydration techniques. We design tailored systems with precise control of oxygen, temperature, and timing — all aligned with your process, capacity, and safety requirements.

Unlock your seeds’ potential with a priming solution by SPH.

Seed Priming Installations

Seed priming boosts germination and breaks dormancy through controlled hydration techniques. We design tailored systems with precise control of oxygen, temperature, and timing — all aligned with your process, capacity, and safety requirements.

Unlock your seeds’ potential with a priming solution by SPH.

Seed Cleaning and Sizing Installations

Which cleaning and sizing solution best suits your business and needs? We are happy to think along with you!

SPH Seed Moisture Content Conversion Table

This table clearly shows the relationship between absolute seed moisture content (MC) and relative humidity (RH) for various seed crops, as well as equilibrium moisture content.

In Seed Processing Holland’s drying systems, air flows are monitored with RH sensors both below the seed bed and above the seed bed during the drying process, ensuring precision at every drying stage.

The table allows conversion from relative humidity to absolute moisture content. A commonly used target for final water activity after drying is 30% RH. It is important to note that the RH-MC relationship varies for different seed crops. By maintaining a well-controlled, dehumidified air drying process, you can ensure the quality and shelf life of your valuable seeds.

Examples of customized customer cases

For over 55 years, we have had the privilege of completing many projects for our global clients. We always work closely with them to realise the best solution that fits the available space and meets the client’s needs.